Kester NP545是一种零卤素、无铅免洗的锡膏,有12个月的常温保质期。

Product Description

Kester NP545 is a zero-halogen, lead-free no-clean solder paste formula designed for consistency and repeatability. NP545 is extremely stable and has an unrefrigerated shelf life of 12 months with no print or solderability degradation. NP545 consistently delivers paste transfer efficiencies of 0.55 to 0.5AR. The paste is also fully capable of printing and reflowing 01005 components, even in air reflow, with minimal graping behavior. NP545 is classified as ROL0 per IPC J-STD-004B.

Performance Characteristics:

■ Zero-halogen

■ Consistent print performance to 0.5AR

■ Excellent shelf life, 1 year in both refrigerated and room temperature conditions

■ Exceptional printing relax & recovery, and printer friendly

■ Low QFN/BGA voiding

■ Reflowable in air and nitrogen

■ Wide reflow profile window with good solderability on various PCB surface finishes

■ Excellent cosmetics and a clear residue

Standard Applications:

Stencil Printing: T3 = 88.5% Metal T4 = 88.3% Metal

RoHS Compliance

This product meets the requirements of the Restriction of Hazardous Substances (RoHS) Directive, 2015/863 for the stated banned substances.

Physical Properties

Viscosity (typical): 1450 poise Malcom Viscometer @ 10 rpm and 25°C Initial Tackiness (typical): 30 grams Tested to J-STD-005, IPC-TM-650, Method 2.4.44

Slump Test: Pass Tested to J-STD-005, IPC-TM-650, Method 2.4.35

Solder Ball Test: Pass Tested to J-STD-005, IPC-TM-650, Method 2.4.43

Reliability Properties

Copper Mirror Corrosion: Low Tested to J-STD-004B, IPC-TM-650, Method 2.3.32

Copper Corrosion: Low Tested to J-STD-004B, IPC-TM-650, Method 2.6.15

Surface Insulation Resistance (SIR): Pass Tested to J-STD-004B, IPC-TM-650, Method 2.6.3.7

Surface Insulation Resistance (SIR):Pass Tested to J-STD-004A, IPC-TM-650, Method 2.6.3.3

Halogen Content: None Detected Tested to J-STD-004B, IPC-TM-650, Method 2.3.41 (ref. EN 14582)

Electro Chemical Migration (ECM): Pass Tested to J-STD-004B, IPC-TM-650, Method 2.6.14.1

Availability

NP545 is available in the Sn96.5Ag3Cu0.5 alloy with a type 3 and 4 powder mesh. Type 4 mesh size is recommended for

standard and fine pitch applications. NP545 is also compatible with other SnAgCu alloys in similar melting range to the

listed alloys. For specific packaging information refer to Kester’s Solder Paste Packaging Chart for available sizes. The

appropriate combination depends on process variables and the specific application.

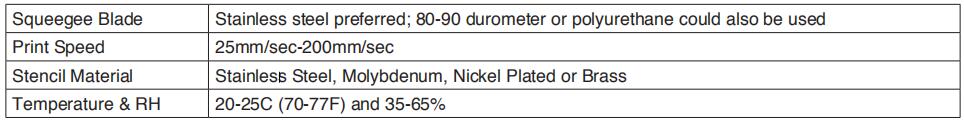

Printing Parameters

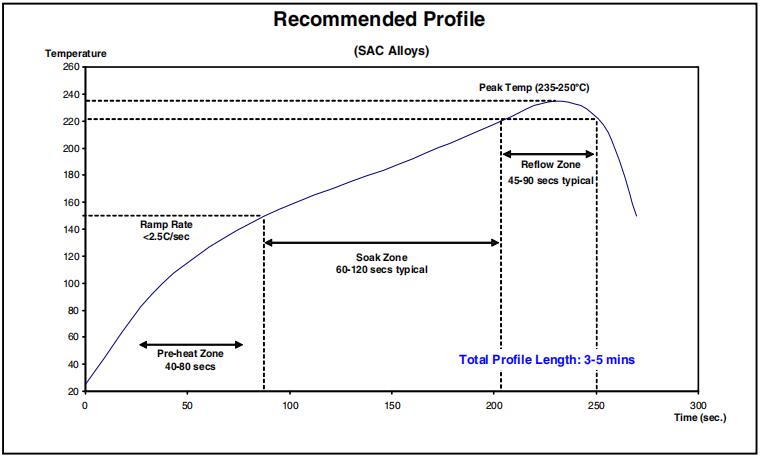

Recommended Reflow Profile

The recommended convection reflow profile for NP545 formula made with SAC alloys is shown here. This profile is simply a guideline. NP545 has excellent solderability and wetting across a wide range of profiles, with similar performance in air and nitrogen. Your optimal profile may be different from the one shown based on your oven, board and mix of defects. Contact Kester Technical Support if you need additional profiling advice.

Cleaning

NP545 is a no-clean formula. The residues do not need to be removed for typical applications. Although NP545 is designed for no-clean applications; its residues can be removed using automated cleaning equipment (in-line or batch) with a variety of readily available cleaning agents.

Storage, Handling and Shelf Life

NP545 has a shelf life of 12 months from the date of manufacture when handled properly at 0-10°C (32-50°F) or when handled at room temperature (up to 27°C/80°F). If refrigerated, NP545 should be stabilized at room temperature (27°C/80°F) prior to printing. Please contact Kester Technical Support if you require additional information on the storage and handling of this material.

Health and Safety

This product, during handling or use, may be hazardous to your health or the environment. Read the Safety Data Sheet and warning label before using this product.